5 important factors worth considering when looking for the best jigsaw blade for plexiglass

Choosing the right jigsaw blades for cutting plexiglass is important for getting clean and precise cuts. You need to pay attention to key factors like the type of material, the number of teeth per inch, and the design of the blade. These elements all affect how well your cuts will turn out. It’s crucial to understand how these factors work together and how they can impact the quality of your cuts when working with plexiglass. By focusing on these factors, you can make sure your cutting experience with plexiglass goes smoothly and successfully.

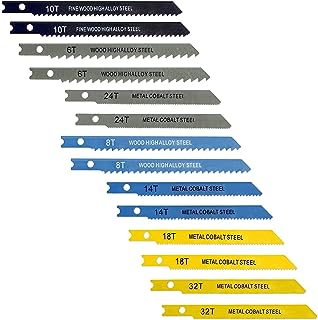

See our guide to the best jigsaw blade for plexiglass.

Material of the blade

When choosing a jigsaw blade to cut plexiglass, the type of blade you choose is important for the success of your project. A carbide-tipped blade is a good choice because it is strong and precise when working with delicate materials like plexiglass. The sharpness and toughness of carbide make it perfect for making clean cuts without causing chipping or cracking in the plexiglass, giving your project a professional look.

On the other hand, using a standard steel blade to cut plexiglass may not give you the best results. Plexiglass is hard and can quickly dull a steel blade, resulting in rough edges and potential damage to the material. By investing in a high-quality carbide-tipped jigsaw blade made specifically for cutting plexiglass, you can ensure that your blade lasts longer and that your cuts are of superior quality, improving the overall appearance of your project.

Tooth design

When choosing a jigsaw blade for cutting plexiglass, the design of the teeth is really important. Blades with fine teeth made for delicate materials like plexiglass can give you clean and precise cuts. These blades have a special design that helps you cut smoothly without chipping or cracking the plexiglass. Even though they may cost more at first, they will make your project look more professional.

If you don’t pay attention to the teeth design when buying a blade for plexiglass, you might end up with rough edges, splinters, or even damage the material. It’s crucial to think about the tooth design when picking out a blade to make sure it performs well and lasts a long time. By choosing the right tooth design, you can improve your cutting experience and make your plexiglass projects look better.

Blade thickness

When choosing a jigsaw blade for cutting plexiglass, it’s important to consider the thickness of the blade. A thin blade, with more teeth per inch, is best for making intricate cuts and curves in plexiglass because it creates less heat and reduces the chance of chipping or cracking the material. Using a thin blade ensures precise cuts and a polished finish for a professional look.

On the other hand, a thick blade can cause friction, leading to overheating and potentially damaging the plexiglass, lowering the quality of your work. Investing in a high-quality thin blade not only improves cutting performance but also makes the cutting process safer. A thin blade designed for plexiglass reduces the risk of kickbacks and blade deflection, providing a smooth and controlled cutting experience.

Precision is crucial when working with delicate materials like plexiglass, and choosing the right blade thickness is key to getting the results you want. In crafting and woodworking, where attention to detail is important, using a thin jigsaw blade for cutting plexiglass can make a big difference in achieving flawless and professional outcomes.

Blade length

When choosing a blade to cut plexiglass with a jigsaw, the length of the blade is important for making accurate cuts. A longer blade gives you more stability and control while cutting, resulting in smoother edges and less risk of damaging the plexiglass. It also allows you to cut through thicker plexiglass easily, making it versatile for different woodworking projects. Even though a shorter blade might seem better for detailed cuts, the advantages of a longer blade outweigh any drawbacks and make it a good investment for professional results.

Ultimately, the length of the blade you choose greatly affects the quality of your work when cutting plexiglass with a jigsaw. Longer blades improve precision and control, making it easier to cut different thicknesses of plexiglass. By understanding the importance of blade length in improving your cutting experience, you can enhance your craftsmanship and achieve smooth cuts that highlight your attention to detail and expertise in working with plexiglass.

TPI (teeth per inch)

When buying jigsaw blades for plexiglass, it’s important to look at the teeth per inch (TPI) of the blade. Choosing a blade with a higher TPI is best for cutting plexiglass. More teeth per inch will give you smoother and more precise cuts, reducing the risk of damaging the delicate material. Even though you might be tempted to pick a blade with fewer teeth for faster cutting, it’s not worth the risk of ruining the plexiglass.

When cutting plexiglass, accuracy is crucial, so choosing a high TPI jigsaw blade is essential. By investing in high-quality tools, like a blade with fine teeth, you’re setting yourself up for success with your project. Each tooth on the blade is important for making clean cuts on the plexiglass, underscoring the significance of a high TPI. Ultimately, being intentional about prioritizing TPI when selecting a jigsaw blade for plexiglass is a proactive step towards achieving excellent results in your cutting projects.

Conclusion

In short, it’s important to pick the right blade when cutting plexiglass in order to get smooth, precise cuts without any damage. Using a blade made for acrylic materials helps DIYers and pros alike achieve great results. Knowing how to choose the right blade and using the best techniques for cutting plexiglass can help people make the most of their jigsaw tools and tackle projects with confidence. Want more info on iron, check the best iron.